Angle Encoders Explained

A complete guide exploring what angle encoders are, their types, key characteristics, benefits, applications, and how to choose the right one.

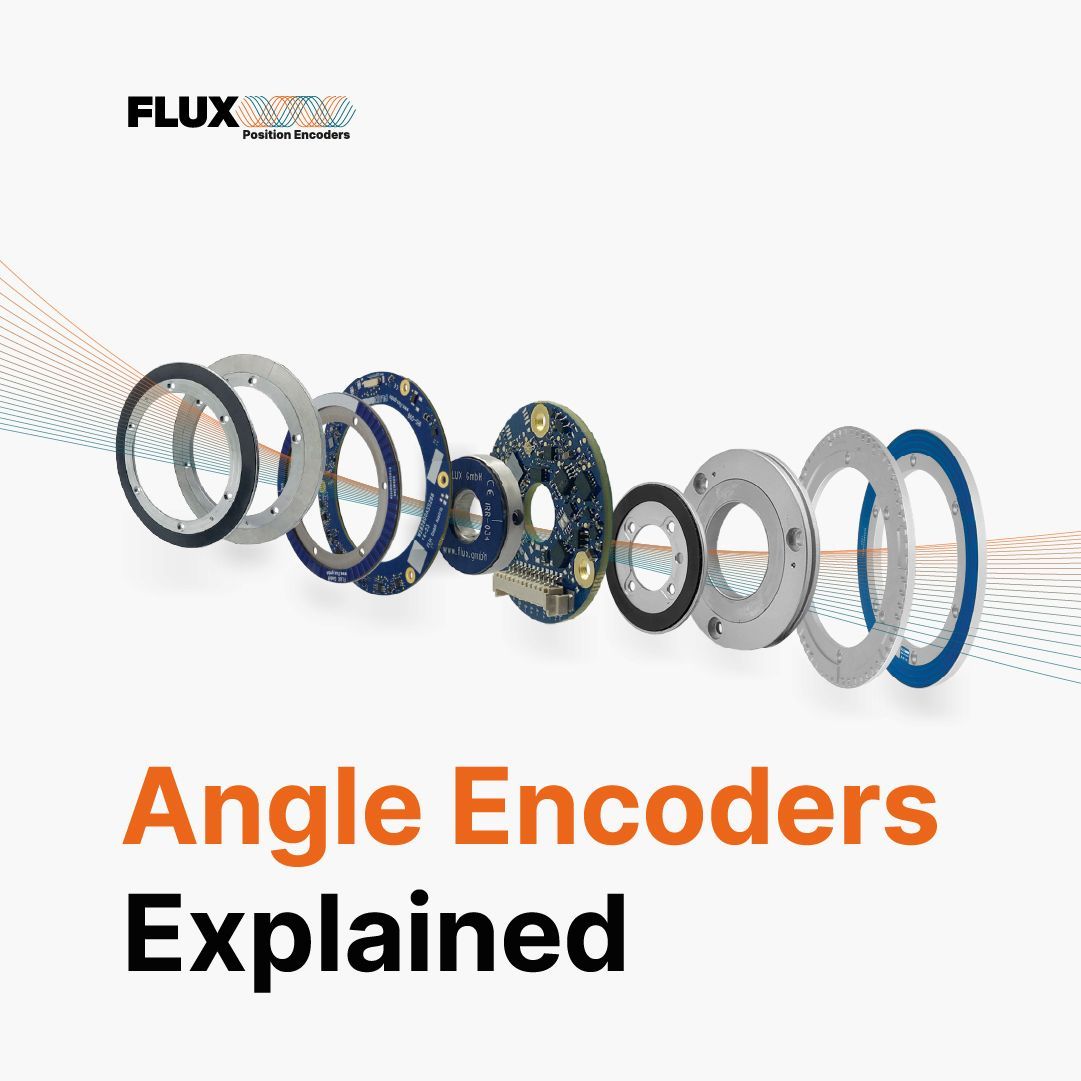

What Are Angle Encoders?

Angle encoders are sensors designed to measure the exact rotational angle or position of a shaft and provide precise digital feedback. They are a subset of rotary encoders, typically optimized for high-precision angular position measurement. Unlike general rotary encoders, which may measure rotation speed or incremental position, angle encoders focus on delivering accurate absolute or incremental angle data for precise motion control. In many designs, they are mounted directly on the shaft to avoid mechanical backlash errors and are widely used in robotics, automation, and industrial applications requiring high precision.

Types of Angle Encoders

Angle encoders vary based on their sensing technology and output type. Common technologies include:

- Optical: High accuracy using light and coded disks. Sensitive to dust, vibration, and misalignment.

- Magnetic: Use magnetic sensors. Robust in dirty environments but offer moderate accuracy.

- Capacitive: Detect changes in capacitance. Resist magnetic fields but can be affected by moisture.

- Inductive: Use electromagnetic induction to determine position. Highly resistant to contaminants, temperature changes, and EMI.

- GMI®: A patented technology that uses changes in impedance under magnetic fields to provide precise position feedback.

- Resistive (Potentiometric): Legacy technology. Low cost but limited in accuracy and durability.

Encoders are available as incremental (providing relative position and requiring homing) or absolute (delivering exact position at all times). Absolute encoders are typically favoured in high-precision applications due to their ability to retain position data even after power loss.

What Are the Key Characteristics of Angle Encoders?

Angle encoders have key characteristics that determine their performance and suitability:

- Accuracy & Resolution: Deliver precise angle measurements down to arcsecond levels for superior control.

- Absolute Positioning: Provide true absolute angle feedback without requiring homing after power loss.

- Environmental Robustness: Withstand dust, moisture, metal particles, and electromagnetic interference with high IP ratings.

- Compact Form Factor: Slim, lightweight designs enable easy installation in tight spaces.

- Durability: Contactless sensing ensures long service life and minimal maintenance in demanding environments.

Applications of Angle Encoders

Angle encoders provide precise rotational feedback essential for motion control and positioning in various industries. Common applications include

- Machine Tools: Precise position feedback for CNC machines and grinders.

- Semiconductors: Accurate motion control in wafer processing equipment.

- Industrial Robots: Enhanced joint and arm positioning for automation.

- Aerospace Surveillance: Reliable tracking in surveillance and monitoring systems.

- Satellite Communication: Precise antenna positioning for signal accuracy.

- Drone Control: Accurate orientation feedback for UAV stability and maneuvering.

How to Choose the Right Angle Encoder

Choosing the right angle encoder depends on your application and environment. The key factors to consider are:

- Accuracy & Resolution: Choose encoders that meet your precision requirements, with higher-bit resolution for greater accuracy.

- Environmental Suitability: Select encoders that can withstand dust, moisture, vibration, and electromagnetic interference based on your environment.

- Output Type: Decide between absolute encoders for true position feedback or incremental encoders for relative motion, ensuring compatibility with your system.

- Size & Mounting: Consider compact, frameless, or hollow-shaft designs for space-saving and easy installation.

- Durability & Maintenance: Choose contactless encoder technologies to ensure extended lifespan and minimal maintenance requirements.

What are Inductive Angle Encoders?

Inductive angle encoders are precision sensors that measure angular position using the principle of electromagnetic induction. These contactless devices feature a rotor patterned with electrically conductive materials (such as copper), which interact with the stator’s alternating electromagnetic field. As the rotor turns, position-dependent eddy currents are induced in the conductive structure. These currents alter the impedance of the sensing coils in the stator, which are monitored by the electronics.

Known for their high reliability and durability, inductive angle encoders excel in harsh industrial environments where dust, moisture, and vibration are present. Their robust, non-contact design minimizes wear and maintenance, making them ideal for demanding applications.

By delivering consistent, high-precision angle measurements, inductive angle encoders are essential for systems requiring accurate position feedback and long-term operational stability.

For reliable performance in extreme environments, explore FLUX’s IND-MAX inductive angle encoder, engineered to provide robust, high-precision measurement in the toughest conditions.

Benefits of an Inductive Angle Encoder

Inductive angle encoders offer a range of advantages that make them ideal for precise and reliable rotary position measurement in tough industrial settings. Known for their contactless measuring principle, inductive angle encoders provide high durability and accuracy while minimizing mechanical wear. Their robustness against shock, vibration, dust, and moisture makes inductive angle encoders well-suited for harsh environments where traditional sensors may fail.

The IND-MAX inductive angle encoder offers several benefits that make it an excellent choice for precise position measurement in challenging environments:

- Contactless operation: Utilizes a contactless measuring principle to avoid mechanical wear and extend device lifespan.

- High reliability and robustness: Built to perform reliably under shock, vibration, dust, and moisture exposure, suitable for extreme environments.

- High precision: Delivers accurate and repeatable angle measurement essential for demanding applications.

- Wide operating temperature range: Designed to operate effectively in harsh temperature conditions.