Products

Patented Technology & Versatile Functionality

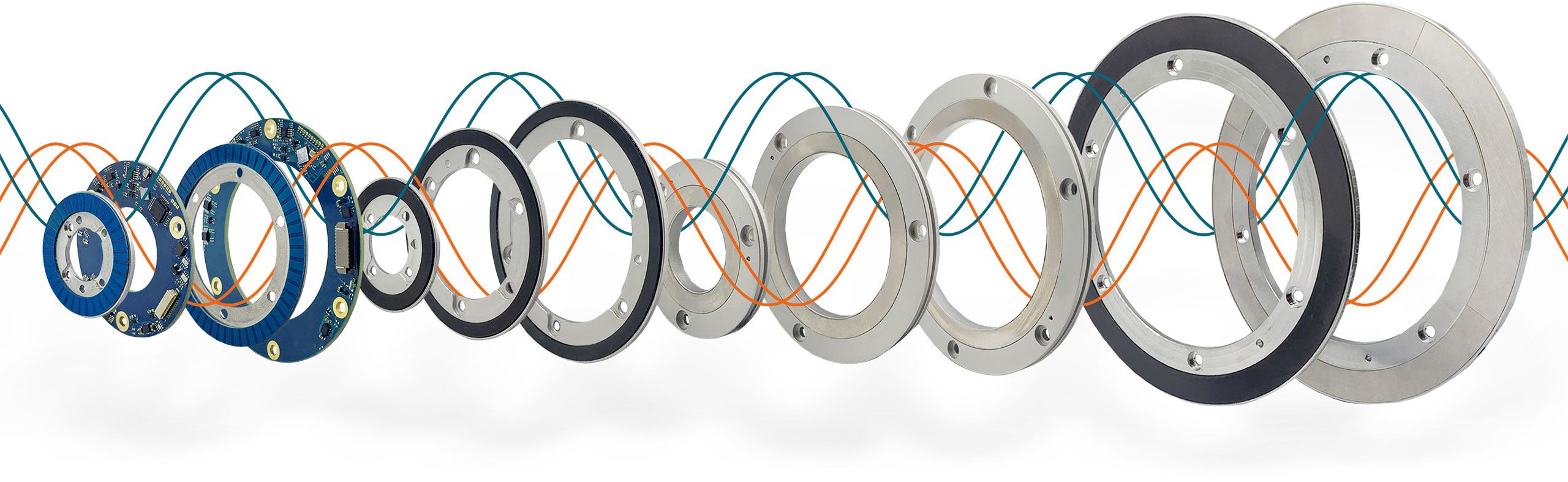

FLUX encoders stand out from alternative measuring systems by offering all their best features in one encoder solution: outstanding accuracy, resolution and repeatability delivered from a small package that is easy to install and operates in clean and harsh environments.

Absolute Frameless Encoders:

Less engineering, increased efficiency.

Users of encoder feedback systems have been looking for a technology that combines the hysteresis-free, high-accuracy performance of an optical encoder with the robustness of an inductive encoder and the large mounting tolerance of a magnetic encoder.

By bringing together the most beneficial features of various encoder systems and incorporating them into a single solution, FLUX encoders unlock new possibilities by reducing time and money spent on engineering.

By bringing together the most beneficial features of various encoder systems and incorporating them into a single solution, FLUX encoders unlock new possibilities by reducing time and money spent on engineering.

GMI® Technology – Innovation Made in Austria

The GMI® encoder technology, developed by FLUX for position measurement, capitalizes in an exceptional way the interaction between magnetic field and electromagnetic induction.

The Giant Magneto Impedance (GMI®) effect is a phenomenon that relies on the skin effect. It is characterized by material’s significant alteration in impedance when exposed to external magnetic fields. Consequently, a sensor’s position relative to a scale generates a signal. FLUX makes full use of these properties for its innovative GMI® position measurement technology.

Patented GMI® encoders combine the high-precision performance of an optical encoder with the robustness of an inductive encoder and the large mounting tolerance and working range of a magnetic encoder. Furthermore, FLUX Encoder Systems work without hysteresis and provide a real-time position update rate.

The Giant Magneto Impedance (GMI®) effect is a phenomenon that relies on the skin effect. It is characterized by material’s significant alteration in impedance when exposed to external magnetic fields. Consequently, a sensor’s position relative to a scale generates a signal. FLUX makes full use of these properties for its innovative GMI® position measurement technology.

Patented GMI® encoders combine the high-precision performance of an optical encoder with the robustness of an inductive encoder and the large mounting tolerance and working range of a magnetic encoder. Furthermore, FLUX Encoder Systems work without hysteresis and provide a real-time position update rate.

Accuracy in Arcseconds

Compact

IP67

Extended temperature range

- Absolute

- Frameless

- Hollow shaft

- Accuracy in Arcseconds

- Resolution up to 25 bits

- Plug-n-play: no field calibration required

- IP67 for use in harsh environments

- Extended temperature range

“As machine units become more integrated, FLUX encoders significantly help to optimize system startup time and operational costs by reducing design and maintenance costs. Thus, we provide our customers with simplified integration and increased efficiency across a wide range of applications.”

Bernhard Lindner

Mechanical Design Engineer, FLUX

IND Technology – Absolute Performance in Narrow Spaces

The inductive technology utilized by FLUX provides a revolutionary solution in the field of inductive absolute encoders and enables the creation of the smallest inductive absolute encoder without sacrificing any performance capabilities.

Exceptional immunity to magnetic and electromagnetic interference allows direct integration into all types of motors whereas the ultra-light, modular design offers a high degree of customization and scalability.

With its unparalleled features, it is suitable for a wide range of industries, including automotive, aerospace, and robotics.

Exceptional immunity to magnetic and electromagnetic interference allows direct integration into all types of motors whereas the ultra-light, modular design offers a high degree of customization and scalability.

With its unparalleled features, it is suitable for a wide range of industries, including automotive, aerospace, and robotics.

Lightweight (14g in total)

Ultra-flat and narrow (thickness < 6mm)

Resistant to dust and electric + magnetic fields

- Absolute

- Frameless

- Hollow shaft

- Easy mounting

- Plug-n-play: no field calibration required

- Resistant to dust and electrical & magnetic fields

- Thickness < 6 mm

- Total weight 14g

Product Porfolio

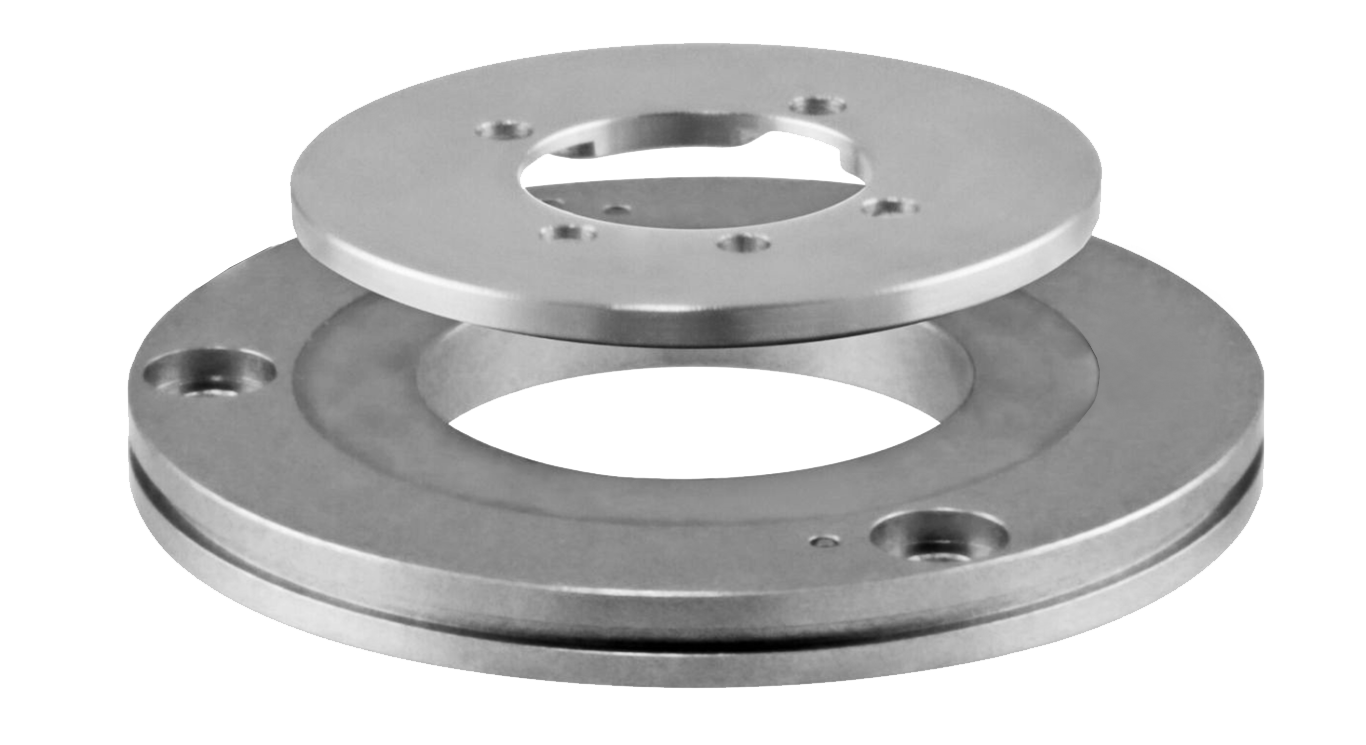

The High Performer

GMI® Angle Encoder

Arcseconds in All Environments

Advanced performance and unique characteristics of FLUX GMI® technology set new standards.

The GMI® Angle Encoder provides the highest accuracy resolution for even the most demanding applications.

- Accuracy in arseconds

- IP67 steel housing for maximum mechanical sturdiness

- 24 bit resolution

- Easy installation with sliding fits and dowel pin holes

- No calibration

The Versatile One

GMI® Rotary Encoder

Precision and Versatility

Accuracy, repeatability, and resolution make this product line a reliable all-rounder for a wide range of applications.

GMI® Rotary Encoders offer an all-inclusive solution to stand out in any situation.

- Flat and robust

- Lightweight

- IP67 aluminium or steel housing

- Wide mounting tolerance

- Easy installation with sliding fits (opt. syncro clamps)

- No calibration

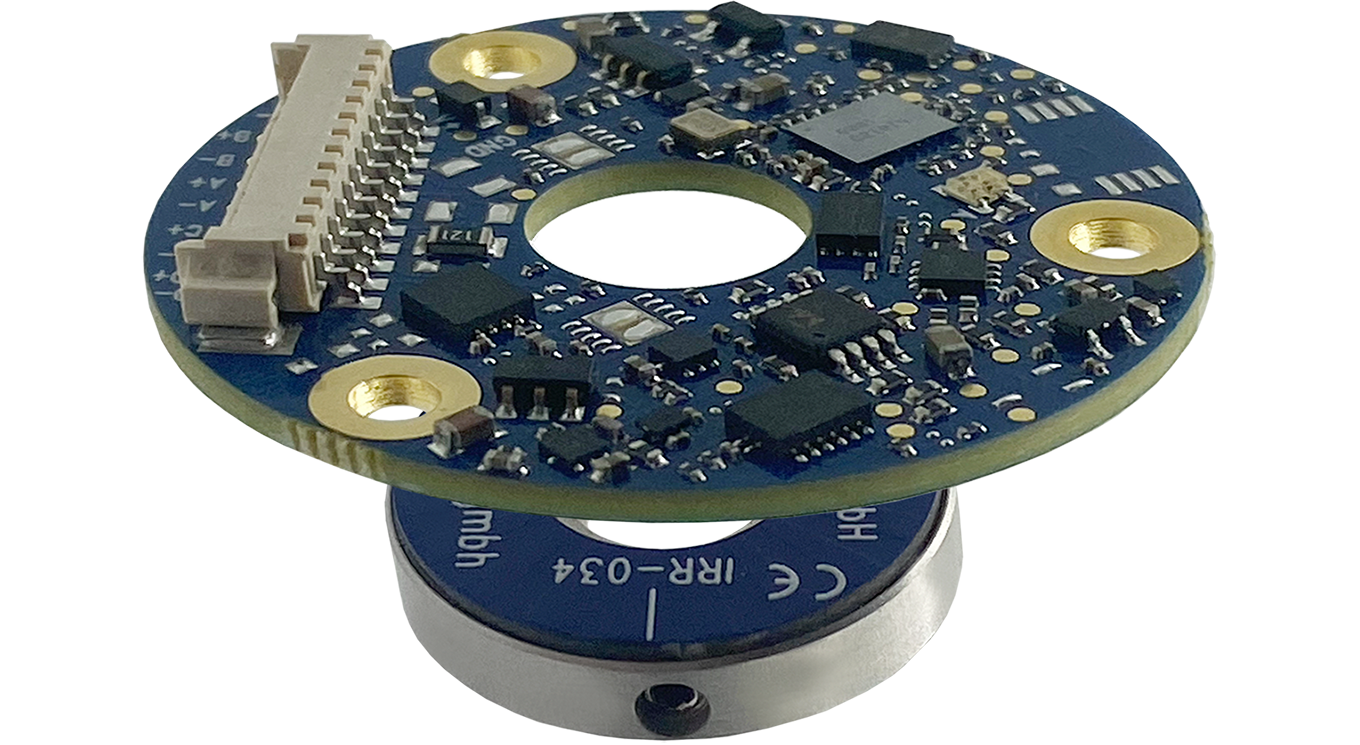

The Compact One

INDUCTIVE Rotary Encoder

Reliability in Narrow Spaces

The Inductive Rotary Encoder is imperturbable despite being an open PCB design that fits and operates wherever it is needed.

For this encoder, there is no place too narrow.

For this encoder, there is no place too narrow.

- Flat and narrow

- Resistant to dust and electrical & magnetic fields

- Thickness < 6mm

-

Total weight 14g

- Easy mounting

- No calibration