Precision in All Environments

Encoder Solutions for Best Performing Motion Systems

FLUX designs and manufactures high-performance encoders for precise position and velocity feedback within closed loop motion control systems. FLUX encoders use proven Inductive and GMI® technologies ensuring maximum precision and reliability for your application.

Lightweight & Compact

Precise & Reliable

FLUX encoders can be used wherever conventional encoders are not feasible.

Latest News

Challenges for Position Encoders in Harsh Environments

Learn how FLUX robust encoders tackle extreme environments and perform precisely and reliable where other me…

INDUCTIVE Rotary Encoders for Critical Medical Applications

Learn how FLUX compact and precise encoders are trusted in crucial medical technology applications including…

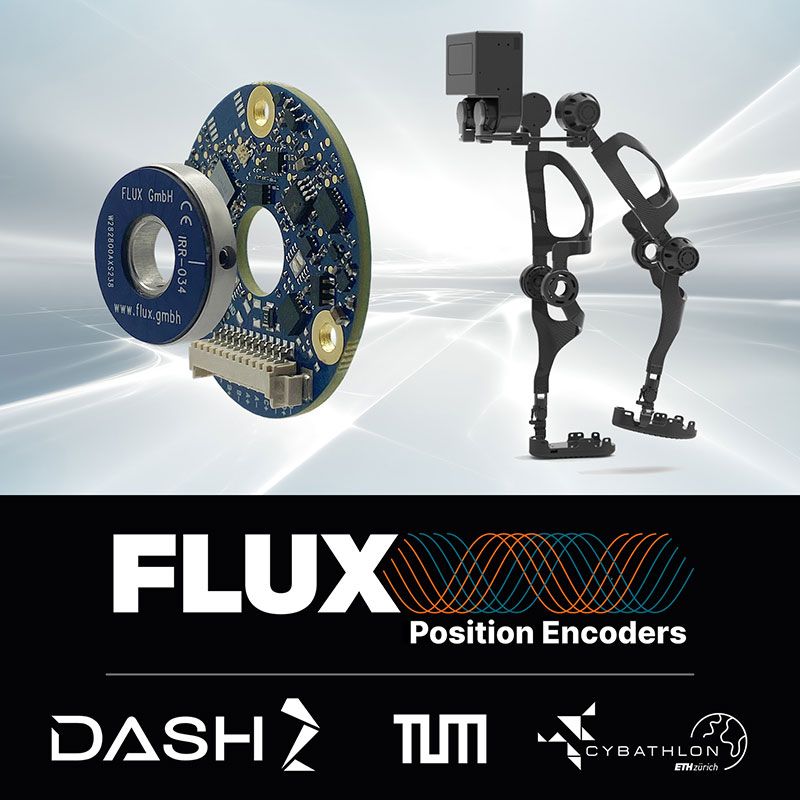

FLUX GmbH Sponsors Technology University of Munich DASH Exoskeleton Team

FLUX GmbH supplies precision inductive rotary encoders for TUM DASH exoskeleton initiative

Choosing Encoders for Surgical and Medical Robots, Interview with Paul Tutzu

FLUX founder Paul Tutzu interviewed on Surgical Robotics Technology to discuss all things encoders for surgi…

Applications

-

Robotics

Providing solutions for robotic joints used in industrial or medical applications, FLUX encoders offer a variety of mounting and mechanical options to ensure an optimal integration without the need for calibration, just plug and play. -

Satcom and Data Communication

Satellite Communications shall provide a reliable and secure means of communication that can be used in a variety of industries, including government, military, aviation, maritime, and commercial sectors. FLUX and its patented GMI® Encoder Technology guarantees for highest performance in harshest environments. -

Machine Tools

High dynamics and accuracy in the arcsecond range without requiring calibration, as well as ingress protection IP67 make FLUX encoders an outstanding choice for machine tools. -

Medical Robotics

Medical robotics has the potential to significantly improve the quality of healthcare, enhance patient outcomes, and reduce healthcare costs. However, development engineers are facing challenges when it comes to safety, reliability and cost-efficiency during the engineering phase. Our encoder solutions provide customized solutions that offer high accuracy, reliability and increased safety to ensure operation in even the most challenging applications. -

UAV

Due to their excellent position and speed control, easy installation features as well as a weight-reduced and flat profile for both, rotor and stator, the FLUX Encoder Systems are an ideal choice for use in UAVs. -

Industrial Automation

Smart manufacturing, also known as Industry 4.0, refers to the use of advanced technologies such as artificial intelligence, the Internet of Things (IoT), and data analytics to improve the quality of manufacturing processes. Our encoders solutions support smart manufacturing processes by easy installation options, minimized downtime and less maintenance effort to increase efficiency and productivity. -

Semiconductor Industry

Precision in the arcsecond range, 360 degree scanning, and intrinsic eccentricity correction provide the ideal basis for applications within the semiconductor industry. -

Videography and Gimbals

Gimbals are commonly used in photography and videography to stabilize cameras and other imaging equipment, allowing for smooth and steady footage even when the camera is moving or shaking. Enabling maximum accuracy performance within arcseconds, FLUX GMI® Angle and GMI® Rotary Encoders are designed for applications that need precise measurements but in conditions where high shocks and vibrations are common.

Our encoders perform where others fail.

FLUX encoders are ideally suited to harsh environments where traditional technologies can prove unreliable. Our Inductive encoders offer excellent precision, small and narrow form factor, simple installation with wide mounting tolerances and are generally unaffected by foreign matter.

We have thousands of product configurations available as standard on short lead-times with options for modification and complete custom solutions.

PATENTED TECHNOLOGY

HIGH-TECH MADE IN AUSTRIA

Product Portfolio

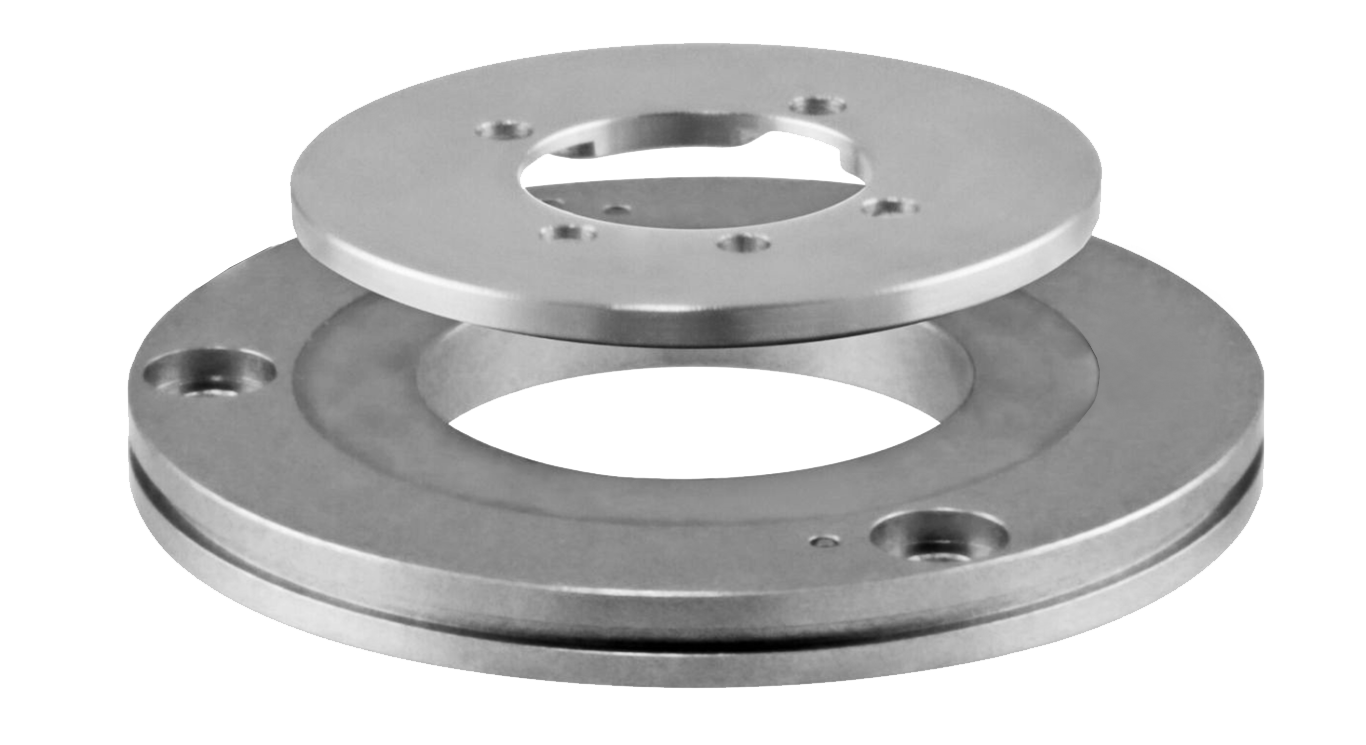

The High Performer

GMI® Angle Encoder

Arcseconds in All Environments

Advanced performance and unique characteristics of FLUX GMI® technology set new standards.

The GMI® Angle Encoder provides the highest accuracy resolution for even the most demanding applications.

The GMI® Angle Encoder provides the highest accuracy resolution for even the most demanding applications.

The Versatile One

GMI® Rotary Encoder

Precision and Versatility

Accuracy, repeatability, and resolution make this product line a reliable all-rounder for a wide range of applications.

GMI® Rotary Encoders offer an all-inclusive solution to stand out in any situation.

GMI® Rotary Encoders offer an all-inclusive solution to stand out in any situation.

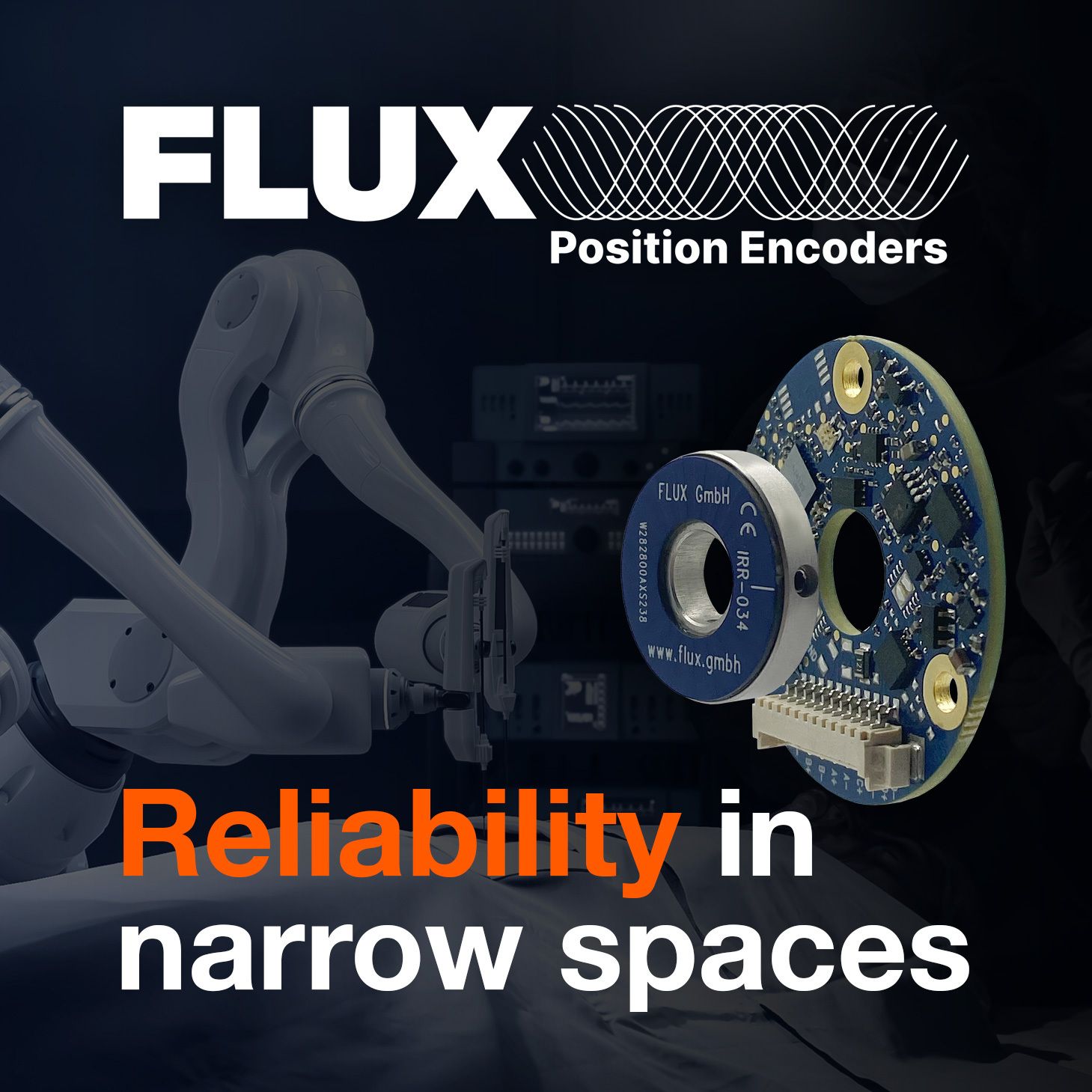

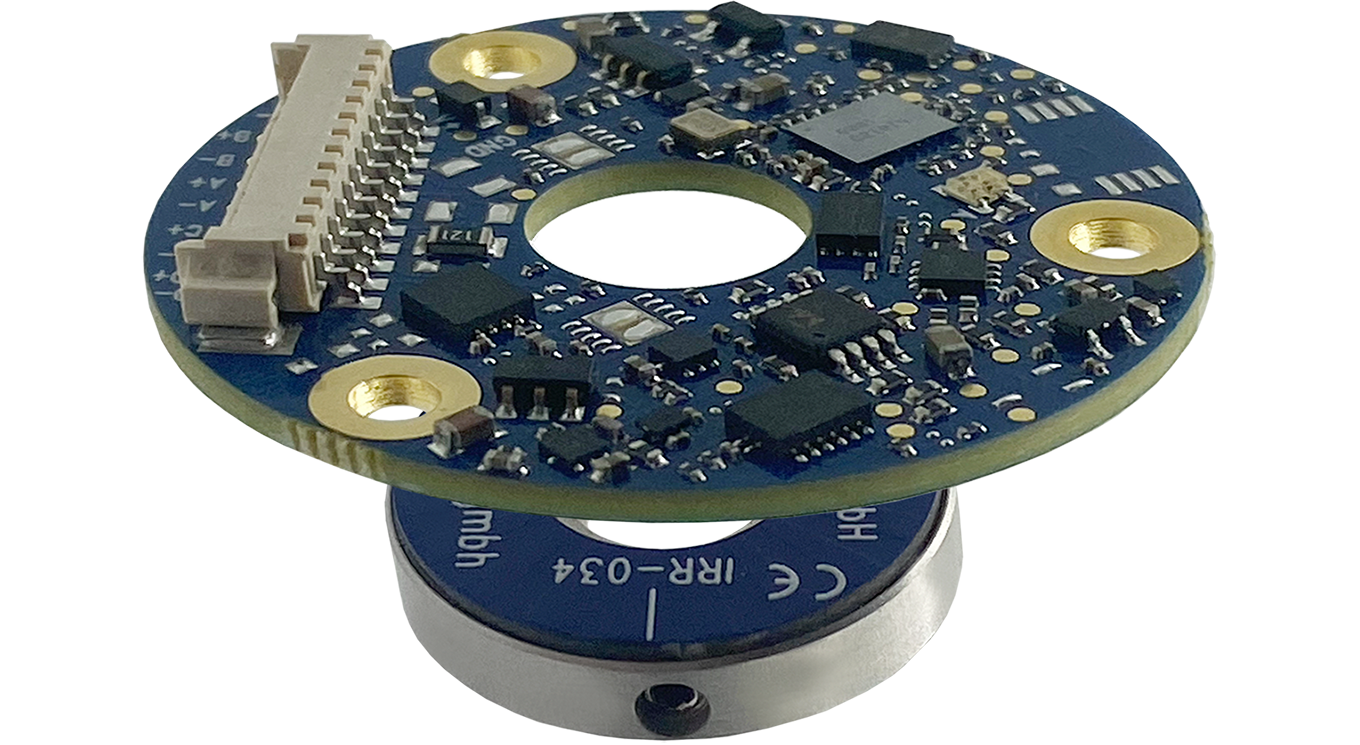

The Compact One

INDUCTIVE Rotary Encoder

Reliability in Narrow Spaces

The Inductive Rotary Encoder is imperturbable despite being an open PCB design that fits and operates wherever it is needed.

For this encoder, there is no place too narrow.

For this encoder, there is no place too narrow.