FLUX GmbH Partners with Product Engineering Services PES

FLUX GmbH Partners with Product Engineering Services to Accelerate Adoption of Precision Encoder Technology in France and Belgium

Braunau am Inn, Austria – April 25, 2024 – FLUX GmbH (FLUX), the high precision encoder company, today announced it has partnered with Product Engineering Services s.a. (PES), a leading provider of assemblies and components for industrial automation and robotics, to expand its presence in France and Belgium.

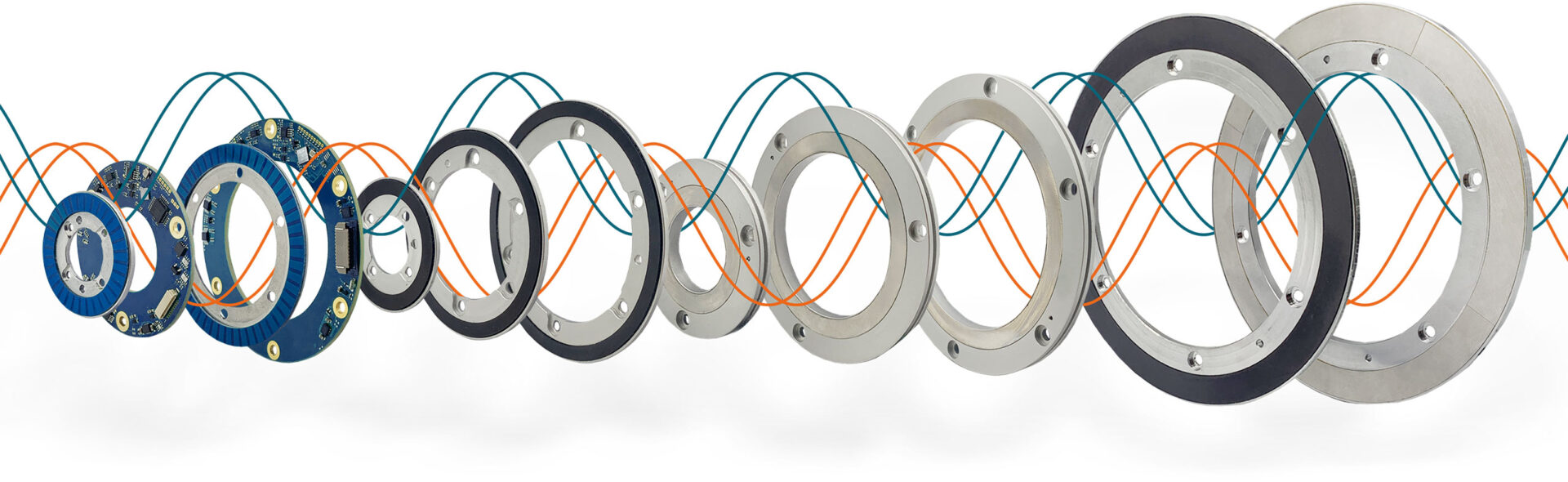

FLUX develops and manufactures high performance encoders for precise measurement of position and velocity within closed loop motion control systems. FLUX encoders differ from conventional measuring principles by delivering the best of all worlds in one encoder. Outstanding performance in harsh environments, excellent precision, and a lightweight and compact form factor.

“The combination of FLUX’s patented GMI encoders and inductive encoders makes its product portfolio truly unique and enables them to meet the needs of a wide range of markets and applications,” said Batiste Mattei, Director Business Unit Motion Control of Product Engineering Services. “We are excited to bring FLUX technology to France and Belgium.”

“At FLUX, we work engineer-to-engineer with our customers to solve complex challenges for mission critical applications in the industrial, aerospace, medical, and marine sectors,” said Paul Tutzu, Founder & CEO of FLUX. “As our business continues to grow, it is important that we expand our network of established, value-add partners globally.”