Revolutionising Encoders: How FLUX’s GMI Technology is Shaping the Future

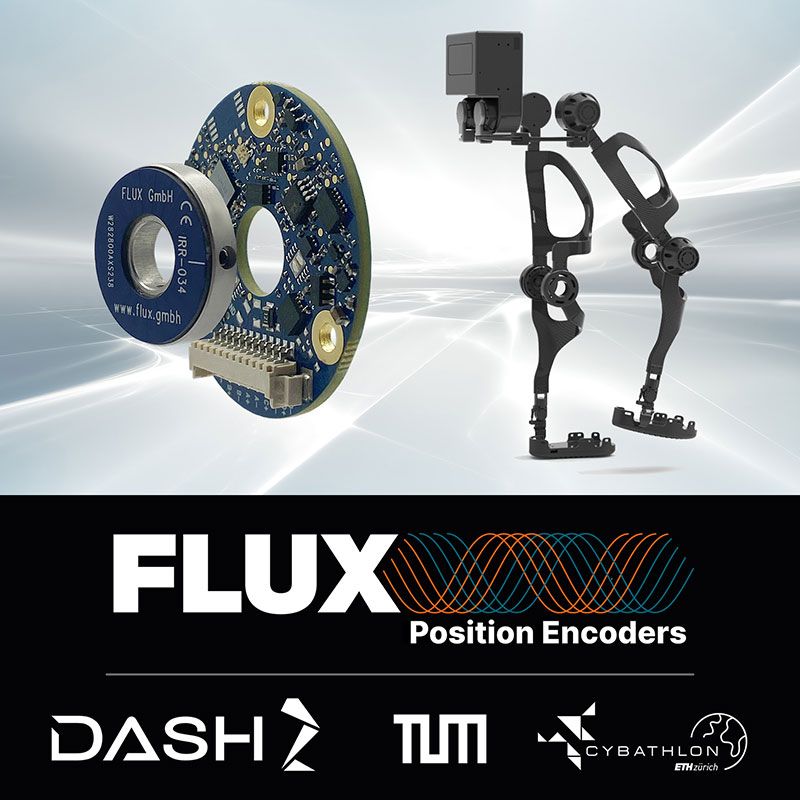

In the fast-evolving world of Industry 4.0, staying ahead means embracing innovations that push the boundaries of what’s possible. At FLUX, our Giant Magneto Impedance (GMI) encoders are setting new standards for precision and adaptability in diverse applications.

Why GMI Encoders Are a Game-Changer

Our revolutionary GMI technology is a principle that has been around but is now harnessed in a way that transforms encoder technology. The GMI effect involves a material’s change in impedance when exposed to an external magnetic field, which can then be used to measure rotational or linear movement with unprecedented accuracy.

FLUX’s GMI encoders leverage this principle to deliver performance that goes beyond the limitations of traditional sensors. With their advanced design, these encoders are ideal for machine tools, gyro-stabilized platforms, and high-performance test stands.

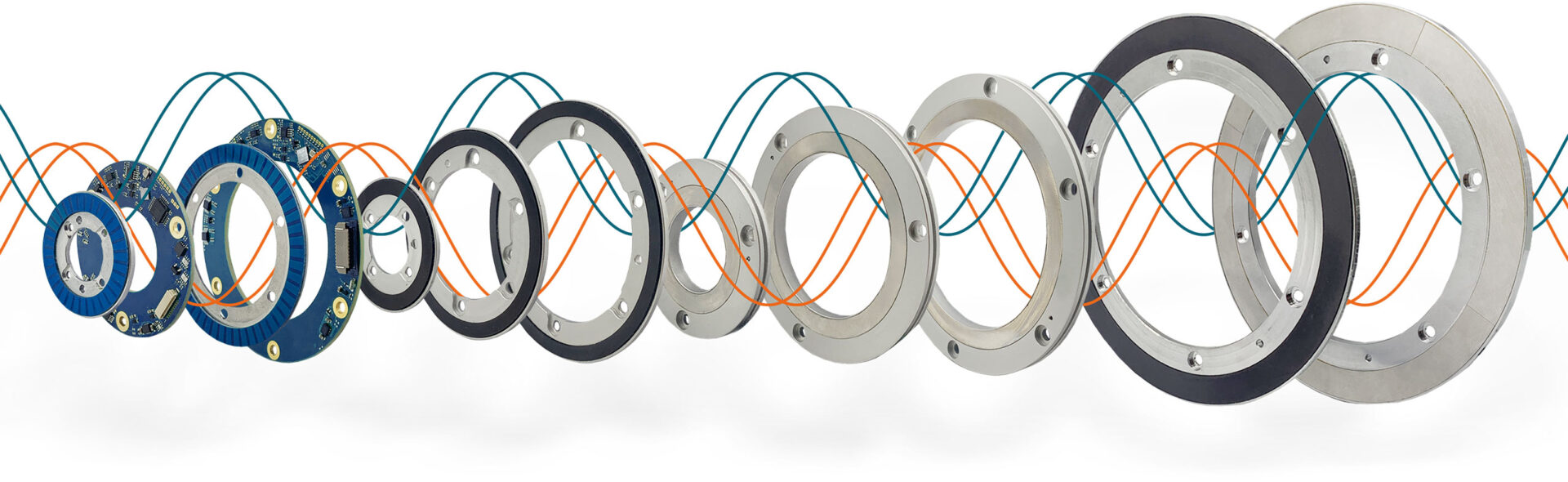

FLUX’s Encoder Portfolio

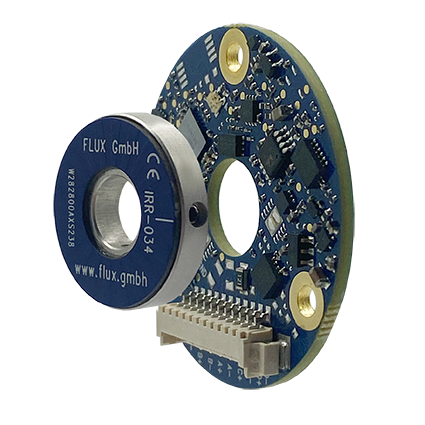

FLUX has three key product lines, two of which utilise GMI technology:

GMI® Angle Encoder (GMI-ANG Series): Provides ultra-fast and precise angle measurements in arcseconds, making it perfect for high-demand applications that require exacting standards.

GMI® Rotary Encoder (GMI-ROT Series): Delivers the benefits of GMI technology in compact spaces, addressing the challenges where traditional encoders fall short.

INDUCTIVE Rotary Encoder (IND-ROT Series): Complements the GMI range with robust and accurate inductive technology encoders, with the IND-ROT Minis being the smallest and most precise on the market.

Applications That Benefit from GMI Encoders

Machine Tools: Our GMI Angle Encoders excel here due to their bearing-less design, which eliminates wear and tear issues associated with traditional encoders. They offer real-time data collection with angular accuracy of ±4 arcseconds, ensuring optimal performance even in challenging environments.

Gyro-Stabilized Platforms: Used in cameras and optical devices, these platforms require encoders that can withstand vibrations and temperature extremes. GMI Rotary Encoders meet these demands with their compact design, high resolution, and resistance to thermal drift.

Test Stands: For material and product testing, where extreme accelerations and speeds are common, FLUX’s encoders offer precise results without being affected by high vibrations or rapid changes in movement.