Capacitive Encoders Vs. Inductive Encoders

Capacitive vs inductive encoders: compare their precision, durability, and performance in our comprehensive guide. Evaluate which technology best meets your application.

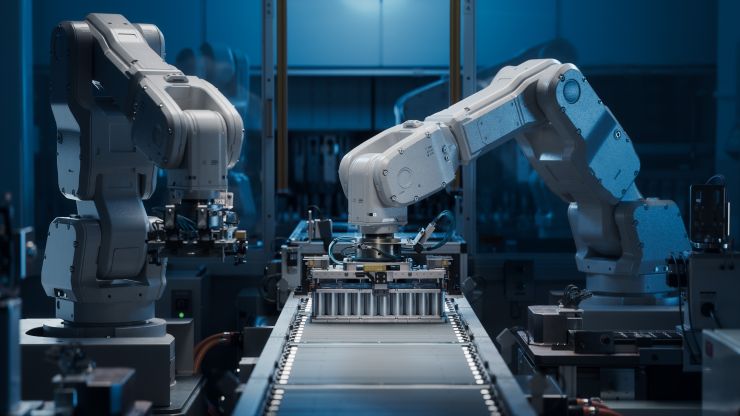

Capacitive encoders and inductive encoders are two common non-contact encoder technologies. Each has its strengths and ideal use cases, however, when it comes to harsh environments inductive encoders are the preferred choice. In this article, we look at the key differences between these two encoder types, highlighting their benefits and trade-offs. If you’re an engineer trying to decide which technology is best for your application, this short article is for you.

Capacitive Encoders

A capacitive encoder determines position by sensing changes in the rotor’s electrical permeability. These variations alter the capacitance of the stator’s sensor structure, generating position signals. Capacitive encoders utilize high-frequency signals to detect changes in the rotor’s permittivity while typically operating with low power consumption. A benefit of capacitive encoders is that the capacitive principle allows for high-resolution measurement. These encoders can also be lightweight and compact which makes them suitable for some robotics, semiconductor and other precision applications.

Despite these advantages, capacitive encoders come with limitations that can make them unsuitable for certain environments. One primary drawback is sensitivity to contaminants. Since capacitive encoders rely on the interaction of electric fields, the presence of dust, moisture, or oil can interfere with operation, leading to accuracy degradation or failure.

Capacitive encoders are not sensitive to magnetic fields, as they do not rely on magnetic principles for operation. While they can be affected by electromagnetic interference (EMI) in industrial environments –such as near motors, drives, or RF-emitting equipment – this can be mitigated by designing them to operate at sufficiently high frequencies. When properly engineered, capacitive encoders can achieve immunity to external electromagnetic disturbances.

Inductive Encoders

An inductive encoder is a position sensor that operates based on the principles of electromagnetic induction. It determines position, speed, and direction by detecting changes in the electromagnetic field. The rotor features a patterned structure made of materials that influence induction in the stator’s sensor. These materials can either increase induction through permeability, decrease it via eddy currents, or both simultaneously. These variations in electromagnetic induction generate position signals, which are then processed and converted into precise positional data.

Compared to capacitive encoders, inductive encoders offer greater flexibility in rotor material selection, allowing materials with different coefficients of thermal expansion (CTE). This enables the use of the same material as the machine it is integrated into, ensuring excellent thermal compatibility. As a result, inductive encoders provide outstanding accuracy and mechanical stability, even under extreme temperature variations and thermal cycles. Inductive encoders offer strong resistance to environmental contaminants, electromagnetic interference, and mechanical wear. These characteristics make them highly suited for demanding applications in industrial automation, aerospace, and defense sectors, where durability and long-term reliability are essential.

Advantages of inductive encoders include:

- Exceptional Durability in Harsh Environments – Inductive encoders excel in applications where exposure to dust, moisture or grease is common

- Resistance to EMI & Noise – Inductive encoders are inherently resistant to electromagnetic interference, making them ideal for environments with high electromagnetic noise, such as industrial machinery and aerospace applications.

- Temperature Resilience – Inductive encoders maintain stability across a wide range of temperatures, from freezing cold to extreme heat, without special protection against humidity ensuring consistent performance in demanding applications.

- Mechanical Robustness – Inductive encoders are very resilient to mechanical shock and vibrations.